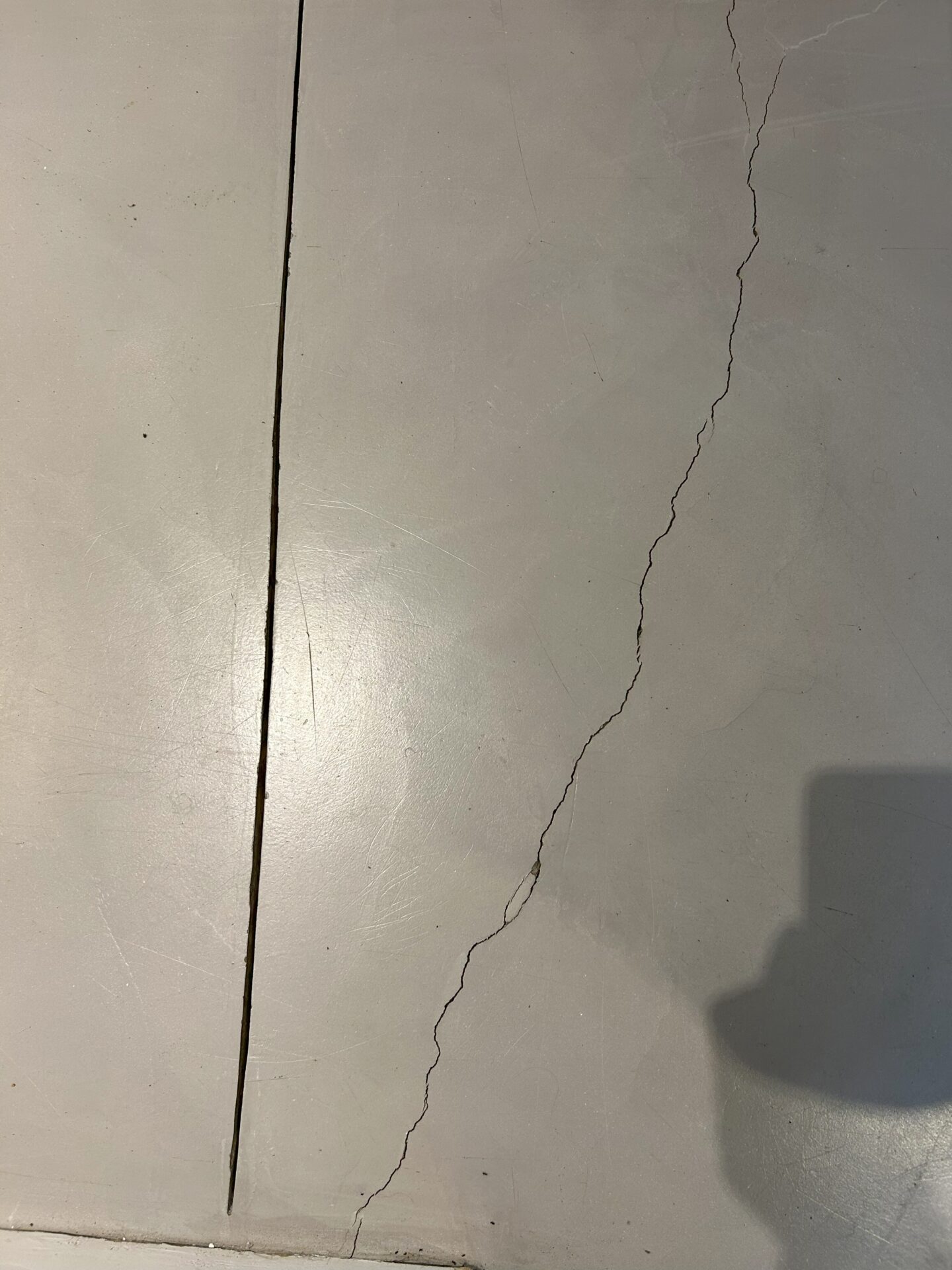

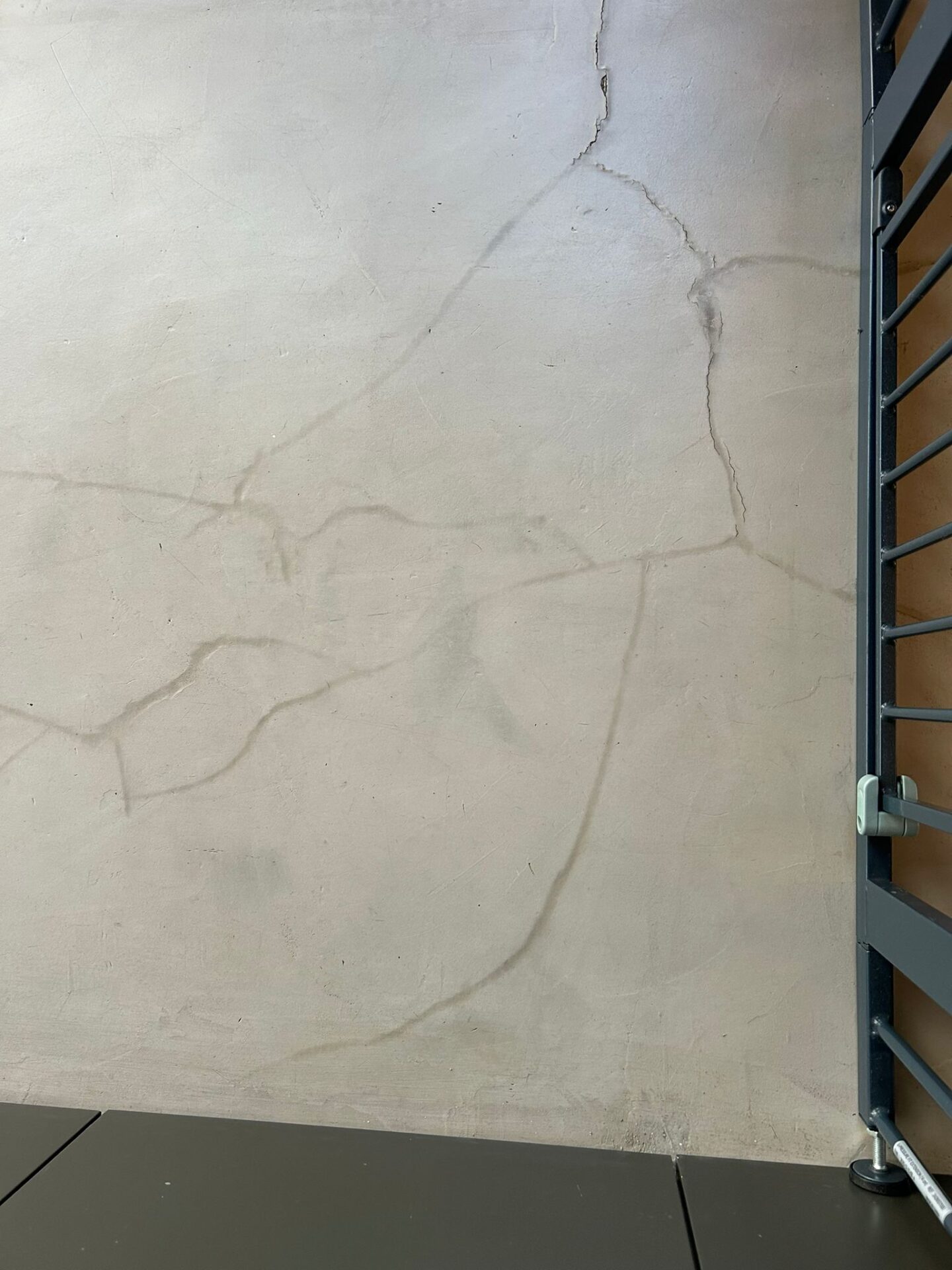

Microcement and Micro-mortar without joints, cracks or fissures

The origin of cracks in microcement in 100% of cases are the result of a crack in the substrate where it has been applied. Therefore, we must discard the belief that microcement cracks. What cracks is the support where the microcement is applied, and as a consequence, as it is an application of approximately 3 mm, this also cracks.

Microcement applied on a substrate is always susceptible to cracking, so the following precautions should be taken. The first is to cover the underfloor heating pipes with a mortar with a load of additives to improve their thermal conductivity and also ensure controlled movement.

In all cases, a decoupling film must be applied to prevent the appearance of any possible cracks or fissures in the microcement or micro-mortar. In addition to doorways, a profile inserted into the floor should be installed to facilitate movement and prevent uncontrolled cracking as far as possible.

In a microcement applied on a cement and sand mortar

that does not have underfloor heating, the consistency of the mortar should be monitored and existing cracks should be repaired. It is possible that in these cases an expansion joint may have to be marked, but this will be decided on a site visit.

In a microcement applied on any type of tile (terrazzo, porcelain, stoneware, etc…), it is necessary to monitor the movement, in some cases imperceptible, of the substrate. Once the substrate has been checked, act on the tiles that move.